Bulk Loading Systems

Bulk Loading Systems

Erie Technical Systems Inc. manufactures standard and custom bulk packaging equipment for industrial applications such as filling bulk bags (FIBC’s), bulk boxes, bulk totes, and bulk drums - all on the same machine. The models range from low-cost, manually operated bulk filling to fully automatic conveyor based bulk filling systems. Several models of the line are shown below.

The ValuMAX®

The ValuMAX®

The ValuMAX® bulk bag filler from Erie Technical Systems Inc. is a low cost and simple bulk bag filler in heavy duty structural steel construction. It is designed to be an inexpensive solution and easy to use. The ValuMAX® bulk bag filler features a 2-post design open in the front for quick removal of the bulk bag by a forklift. The bulk bag straps are supported by two adjustable arms and the bag will sit on a pallet for removal.

ValuMAX® bulk bag filling system adjusts in minutes for bulk bag sizes from 35” wide x 35” deep x 35” tall up to 48” wide x 48” deep x 55” tall. The ValuMAX® bulk bag filler frame supports up to 2,500 pounds of product and, although low-cost, many manual options are available such as an integral weigh scale; a manual, pneumatic or electric slide gate valve; and a product surge hopper.

Typical Applications

• Dust Collector By-Product bagger

• Dry bulk solids

• Aggregate

• Process by-products

• Food

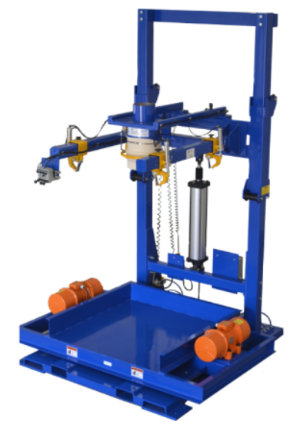

DensiMAX™ Bulk Bag/FIBC

DensiMAX™ Bulk Bag/FIBC

The DensiMAX™ Bulk Filling Stations fill, vibrate and weigh bulk bags, FIBC’s, IBC’s, bulk boxes, bulk totes or bulk drums. The DensiMAX™ Bulk Bag Filling Station is a semi-automated Bulk Filling Station that features PLC control. The level of automation for the bulk filling system will be dependent on the options selected when specifying the machine.

When filling FIBC’s, IBC’s, bulk boxes, bulk totes or other types of bulk containers the system uses information from the scale to control many of the features of the machine, cutting the fill time per container. These heavy-duty systems are among the best available today, offering great value and durability.

DensiMAX™ Bulk Bag/FIBCDensiMAX™ Bulk Bag/FIBC Features

• Semi-Automatic Filling Operations

• Weigh, Fill, and Vibrate (Densify) Simultaneously

• Highly Accurate

• Modular construction with growth options

• Options available for Pallet Dispensers, Pallet Stackers, Pallet conveyors, Feed Devices and Controls

• Testing at Erie Technical Systems to evaluate your material

• Easily Integrated into existing processes and control systems with Ethernet communication

Bulk Unloading Systems

Bulk Unloading Systems

Erie Technical Systems, Inc. manufactures manual and automatic equipment for unloading all types of bulk materials. Our products include bulk bag unloaders, bulk box dumpers, bulk bag conditioners.

The UltiMAX® Bulk Bag Unloader

The UltiMAX® Bulk Bag Unloader

Erie Technical Systems UltiMAX™ Bulk Bag Unloaders manually or automatically unload bulk bags. Also known as Bulk Bag Dischargers, they safely support bulk bags with a lifting frame.

The frame can be used with a forklift or an optional hoist and trolley system. Once the bulk bag is in place, the operator can untie the bottom bag spout in a dust-tight environment. Flow out of the bag can then be controlled either manually or automatically.

UltiMAX™ can be paired with Erie Technical Systems FlexMAX®, ValuMAX®, or a vibratory feeder to create a system to meet the specifications of each individual application.

UltiMAX™ Bulk Bag Unloader Features

• Heavy duty thick wall structural tubing construction

• Heavy duty Support Frames can hold up to 5,000 pounds (2268 kg)

• Modular frames sections allow hoists and discharge conveyors to be added in the field

• Automatic or Manual operation

• Dust-tight bag untie box

PalletMAX™ Pallet Dispenser for Conveyor Based Systems

PalletMAX™ Pallet Dispenser for Conveyor Based Systems

Erie Technical Systems Inc. manufactures standard and custom automatic pallet dispensers.

The PalletMAX™ Pallet Dispenser for Conveyor Based Systems dispenser can be loaded with 15-20 standard pallets using a forklift. The lowest pallet is separated from the other pallets and delivered using a chain conveyor. An Allen-Bradley PLC controls the logic and safety interlocks.

Units are available for delivery of 44″to 48″ width or length pallets. Adjustable legs allow for a minimum pallet delivery height of 12.5″.

The PalletMAX™ automatic pallet dispenser also know as a Pallet Inserter, or Pallet Placer, is a heavy duty industrial unit offering long-term maintenance-free operation.

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358