Stedman Crushers

Stedman Crushers

Backed by more than 180 years of industry experience, Stedman Machine Company provides crushing equipment with the highest levels of performance and the lowest possible maintenance. Stedman’s complete line of size reduction equipment (impact crushers, cage mills, and more) provide the best solution for your process, instead of modifying your process to fit the equipment.

Stedman Machine Company provides consulting services, custom design and layout, project planning, full-scale testing and toll processing. in particular, Stedman's 24 hour parts and service department along with a large inventory of wear parts provides the fastest response time for parts and service.

HSI IMPACTORS

Up to 40” feed sizes and 1600 TPH, reduction ratios up to 30:1. Open discharge with no screen or grates to plug. Heaters & air cannons available for wet, sticky materials.

VERTICAL ROLL MILLS

Grind / Dry / Classify. No Minimum Feed Size. Tight particle size distribution. Easy change Grinding Zone. Typical Applications include Coal, Pet, Coke, Lime, Rock Dust, Calcium Carbonate, Activated Carbon, Ores, and Ceramics

CAGE MILL PULVERIZERS

Final product size from 10-200 mesh with capacities up to 200 TPH. Single & multi-row pulverizers with no

hammers or screens. Ideal for wet, sticky materials and blending or cleaning products.

AURORA CRUSHERS

This dual rotor crusher features a dual shaft design that produces a higher throughput and smaller particles. Rotor speed, rotor direction, cutter design, and screen opening size are all adjustable for fine tuning. Ideal for high throughput lumpbreaking for lump breaking for pneumatic conveying or unloading materials.

HAMMER MILLS

Grind, pulverize, and crush a wide range of materials. Utilizes a rain of hammer blows to shatter and disintegrate the material. Hammer mills produce a finish product size that is dependent upon openings in perforated screens or grate bars, number, size and type of hammers; grinding plate setting and rotor speed.

CHAIN MILLS

Cost-effective crushing solution for reducing a wide variety of materials. The simple design features a chain curtain at the impact end to allow for a swinging action requiring little maintenance. Stedman’s chain mill crushers can handle a large volume of tailings per hour. An especially effective fertilizer crusher, Sredman's chain mill crusher series is engineered to break up lumps in superphosphate, triple-superphosphate, granular and conventional fertilizer tailings.

Franklin Miller Inc Grinders & Shredders, Size Reduction

In-line and stand alone

In-line and stand alone

Taskmaster® Inline Grinders employ a powerful twin shaft mechanism to reduce solids in sludge, slurry, wastwater and sewage pipelines. These versatile, processors reduce such materials as rags, plastics, wood, debris, tampons, sanitary napkins and more. In plant operations worldwide they keep pipelines flowing, reducing pump downtime and protecting dewatering equipment such as centrifuges, filter presses and more. In-line grinders are available for pipe sizes of 4" - 30" in models with 3 HP - 25HP drives.

Versatile Taskmaster®stand alone shredders employ a low speed, high torque mechanism for powerful reduction of tough and bulky waste solids. The Taskmaster® comprises a complete line of shredders and shredding systems for a wide range of applications. Stand alone shredders offer 3 HP - 125 HP motors and input openings up to 60"L x 32"W.

Many models offer 1-piece cutter stacks for reduced maintenance and easy replacement.

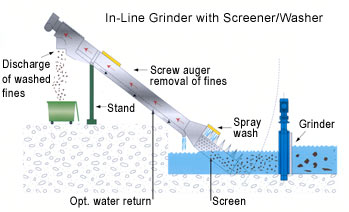

In-Line Grinder with Screener/Washer

In-Line Grinder with Screener/Washer

The SPIRALIFT® SL features Taskmaster® grinding technology in combination with a shaftless screw screen. This system fine screens, washes and conveys solids out of a channel. The discharge is a homogenous, ground filtrate which is washed, compacted and conditioned - ideal for landfill disposal. By combining two technologies into one system, the SPIRALIFT® forms a uniquely effective system. It is a perfect solution for any problematic wastewater flow system such as kitchens, hospitals, correctional institutions, schools, etc.

Combining two proven technologies into one effective system, the result is a reliable operation for grinding, screening, washing, transporting and de-watering of blocking solids.

- Effective for small or large objects such as shoes, cans, blankets, sheets, etc.

- Provides dependable fine screening and washing

- Superior solids capture

- Reduces odor of output particles

- Allows organics to remain in the water flow

- Low headroom above discharge

- Discharge is ideal for landfill disposal

- Scre auger is activated by timer or level

- Auto control system monitors and operates

- Grinders are cartridges of hardened 4140 steel

- Components are available in various models of power and size

How it works

How it works

The powerful grinder reduces the solids to small particles, loosens biological material and increases surface area.

As the solids are discharged from the grinder, the reduced particles are subjected to primary washing by the turbulent channel flow.

The particles are then captured on the screener/washer ’s fines screen and conveyed up the spiral past a spray wash manifold. The compacted particles are finally discharged into a bin, bag or auxiliary conveyor.

Stand Alone Shredders

Stand Alone Shredders

Versatile shredders employ a low speed, high torque mechanism for powerful reduction of tough and bulky waste solids, reducing scrap volume by up to 80%.

Stand alone Shredders are available in a variety of models and sizes. Motors and drives from 3hp to 125 hp meet most shredding applications.

Typically, each unit is supplied complete with control, stand and standard hopper. Shredders can operate as stand-alone or as part of a complete shredding system in dry, wet or pressurized environments.

Shredders have remarkable shredding capabilities on a wide range of materials including: packaging, hospital waste, aluminum cans, PET/HDPE bottles, computer printouts, manufacturing rejects, pharmaceutical rejects, glass/glass containers, plastic purgings and sprues, wood, skids, pallets, crates, steel drums, documents, hides, wastewater, concession waste, newspapers, tires and much more.

Options include:

- Packing Ram

- Feeders and Conveyors

- Special Hopper and Stands

- Output Sizing Screens

- Sealed Design for Submerged Service

- Two-Stage Systems

- Stainless Steel Construction

Crushers and Lump Breakers

Crushers and Lump Breakers

Using impact, shear, compression or abrasion, crushers reduce a variety of solid products to a desired particle size range. Example industrial products that benefit from crushers are chemicals, minerals, food, food ingredients, pharmaceuticals, grain, fertilizer, coal, soap and more.

The material being fed into the crusher can be a solid, lump, chunk or agglomerate. Different models are available designed for dry, gravity or wet systems and can be either inline or open, stand-alone and conveyor-fed as part of a full system. These units can be supplied for low or high temperature environments as well as for pressurized or vacuum systems.

Crushers also solve the problem of discharged materials agglomerating or building up on vessel walls. Installing a crusher breaks up the oversized solids that tend to plug the discharge process.

Ultra-sanitary models are designed with easy interior access, cantilevered design, clean-in-place capability, quick change-over of cutting elements, and a meticulously polished finish. A convenient access door provides fast and easy access to the interior of the cutting chamber for cleaning. The precision aligned, smooth rotating drum with integral teeth rotates through a set of sizing combs. This mechanism produces a once thru, non-destructive crushing action that reduces oversized particles to their basic grain size without over-grind or over-work of material. The result is improved product consistency for enhanced processing, feeding and packaging.

Features include:

- Rugged, one piece, dust tight body construction

- Individually replaceable teeth

- Low vibration and noise

- Shaft seals

- Flanges for convenient connection

- Low headroom design

- Standard models are available in Carbon Steel, T304L or T316L Stainless Steel

- Input openings of 12"x12", 14"x16", 14"x31" and 20"x20"

- Optional hoppers, stands, screens, hard facing and controls

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358