Dust Solutions Inc

Dust Solutions Inc

Dust Solutions, Inc. designs and manufactures products for a unique approach to preventing dust by returning it to your process is the most effective way to create a safe and clean environment. For many years, our complete line of prevention, suppression and wind protection products have addressed breathable and visible problems for a wide array of industries including mining, power generation, biomass, aggregate, pulp and paper, wood products, hazardous waste, marine and bulk handling.

Dry Fog Dust Suppression

Dry Fog Dust Suppression

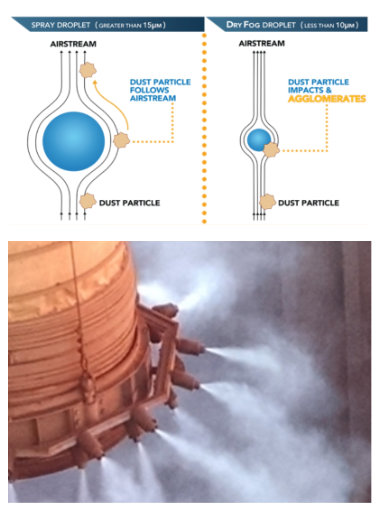

DSI Dry Fog systems are designed and engineered to effectively reduce fugitive dust at material handling points. DSI technology uses air atomizing nozzles that produce water droplets 10 micron or less. These ultra-fine water droplets add less than .5 percent of moisture by weight and attach to like size dust particles and drop them back into the process.

Systems allow for flexible configuration with pre-assembled modular components. Housed in protective enclosures, we supply complete systems comprised of electrical controls, filtration, flow regulation, supply lines and nozzle mounts. If required, DSI can supply all necessary ancillary items including air compressors, air receiver stations, pumps, and self-cleaning secondary filtration systems.

DSI Dry Fog systems significantly reduce fugitive dust from a variety of material handling points, including conveyor transfer points, trippers, reclaimers, crushers, screens, truck dumps, railcar loading/unloading, ship loaders-unloaders, and ash silo discharge chutes.

Systems can meet all requirements for explosion hazard areas. Freeze protection can be provided for systems operating in temperatures as low as -35 degrees F.

Wind Fence Systems

Wind Fence Systems

DustTamer Wind Fence systems reduce dust emissions caused from wind erosion on open stockpiles. DustTamer material is designed to exert a drag force on oncoming wind and reduce wind speeds up to 75% within the sheltered area, preventing dust that is generated by oncoming winds, material loading and unloading, and equipment and vehicle movement from becoming airborne.

DustTamer™ Fabric is knitted from industrial grade woven polyester, resistant to UV rays, in-climate weather and temperature extremes. Its unique ability to be stretched and tensioned to over 500lbs. of pull prevents "flagging" of the material and consequential damage due to abrasion. The slotted design prevents dust from plugging the fabric like basket weave material will do. Systems include all fabric and attachment hardware including brackets, lockbars and tensioning tools for installation.

NESCO Water Spray Systems

NESCO Water Spray Systems

NESCO wet suppression systems control visible dust produced by mining and other material handling operations.

Our high pressure spray systems use state-of-the-art technology to control dust year round without blinding screens or throwing products out of spec.

High pressure sprays use a powerful mist to suppress dust and conserve water without using chemical additives.

Water spray systems are an industry standard method of dust suppression for crushing and screening applications.

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358