Rotary Valves by Carolina Conveying

Rotary Valve Applications

Typical Rotary Valve Applications are:

• Control feed rate from hopper or silo

• Provide airlock on bottom of dust collector

• Provide airlock on bottom of cyclone

• Provide airlock on bottom of filter/receiver

• Provide airlock into a pneumatic conveyor

• Provide airlock into a vacuum conveyor

NOTE: All Carolina Conveyor rotary valves ARE airlocks due to the high tolerance of the tight clearance between rotor and housing. This may not be true of other brands.

Because of the importance of this tight clearance, the number one characteristic of your application will be the product temperature. After temperature, consideration is given to material type and density, rate and capacity, etc.

Rotary Valve Types

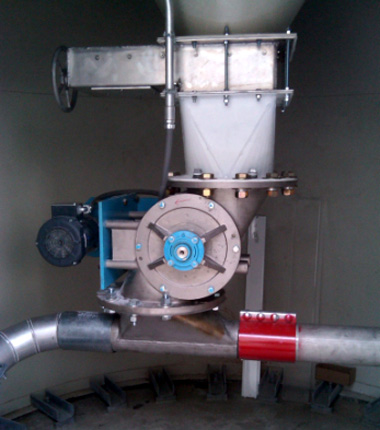

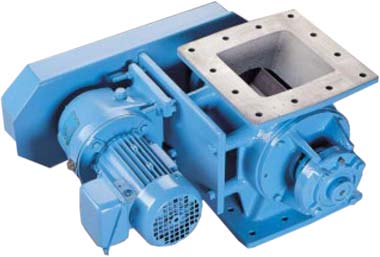

The Carolina Conveyor HD Drop Thru Rotary Valve is the most common model and is chosen for many applications from dust collectors to pneumatic conveying systems. Numerous rotor typesand flanges are availabe for this unit. A square flange and motor and drive are shown in this photo. Features include thick castings and rotor blades, outboard regreasable bearings and gland type shaft seals.

Side Entry (Offset)

The side entry valve is used in applications where product shearing is a concern. The offset inlet allows the product to fill the rotor before it rotates into the housing, eliminating the pinch area. The v-shaped throat also helps push the product away from the shear area.

The side entry valve is used in applications where product shearing is a concern. The offset inlet allows the product to fill the rotor before it rotates into the housing, eliminating the pinch area. The v-shaped throat also helps push the product away from the shear area.

HD Blow Thru Rotary Valve

Used only in pneumatic conveying applications, the HD Blow Thru model includes ports near the bottom that connect directly to the vacuum or positive pressure lines. A very efficient design, the air stream flows right through the rotor pockects and works well for difficult-flow products. This unit is also helpful in limited height locations.

Used only in pneumatic conveying applications, the HD Blow Thru model includes ports near the bottom that connect directly to the vacuum or positive pressure lines. A very efficient design, the air stream flows right through the rotor pockects and works well for difficult-flow products. This unit is also helpful in limited height locations.

Std Duty Rotary Airlock

Designed specifically for lighter duty applications such as gravity flow and for non-abrasive products, these units are very economically priced. They feature a direct drive angle gearbox (shown), inboard bearings and lipseals.

Designed specifically for lighter duty applications such as gravity flow and for non-abrasive products, these units are very economically priced. They feature a direct drive angle gearbox (shown), inboard bearings and lipseals.

Easy Clean Rotary Airlock

The Easy Clean Airlock features a quick release rotor for quick and easy removal. This option is very useful in applications requiring regular cleaning for sanitary and product change purposes. Extra bearings and pins allow two end cover bolts to be reversed and used to separate the end cover and rotor from the housing. Optional slide rails (lower photo) can support the whole assembly in large, heavy rotary airlock applications.

The Easy Clean Airlock features a quick release rotor for quick and easy removal. This option is very useful in applications requiring regular cleaning for sanitary and product change purposes. Extra bearings and pins allow two end cover bolts to be reversed and used to separate the end cover and rotor from the housing. Optional slide rails (lower photo) can support the whole assembly in large, heavy rotary airlock applications.

Carolina Conveyor's Bulk Bag Discharge Station is the result of a full year of R&D with solutions to many challenges voiced by users of other systems. First dust is treated in 4 ways: The full platform seals the bag battom tightly against the dish; Pinch Bars seal off the bag so it is untied while the access door is closed; A larger access door allows movement room for workers while containing the dust; A dust collection ring allows a vacuum connection directly to the top of the platform so dust is swept away immediately as the empty bag is lifted. Safety, quality, efficiency and economy are also engineered into the design.

Carolina Conveyor's Bulk Bag Discharge Station is the result of a full year of R&D with solutions to many challenges voiced by users of other systems. First dust is treated in 4 ways: The full platform seals the bag battom tightly against the dish; Pinch Bars seal off the bag so it is untied while the access door is closed; A larger access door allows movement room for workers while containing the dust; A dust collection ring allows a vacuum connection directly to the top of the platform so dust is swept away immediately as the empty bag is lifted. Safety, quality, efficiency and economy are also engineered into the design.

Carolina Conveying offers a range of heavy duty, robust Ni-Hard wear-back elbows exclusively for the abrasive product field. The Wearback Elbow is ideal for both dilute and dense phase pneumatic conveying systems. All elbows are flanged to ASA 150# pattern. The majority of wear occurs around the outside radius of the elbows, hence the wear-back can be replaced to extend the life of the elbow. The wear-back may be replaced with the elbow in position, eliminating the longer shutdown associated with normal long radius elbows. The wear-back is also interchangeable between the 45 and 90 versions allowing a single spare to be held in stock!

Carolina Conveying offers a range of heavy duty, robust Ni-Hard wear-back elbows exclusively for the abrasive product field. The Wearback Elbow is ideal for both dilute and dense phase pneumatic conveying systems. All elbows are flanged to ASA 150# pattern. The majority of wear occurs around the outside radius of the elbows, hence the wear-back can be replaced to extend the life of the elbow. The wear-back may be replaced with the elbow in position, eliminating the longer shutdown associated with normal long radius elbows. The wear-back is also interchangeable between the 45 and 90 versions allowing a single spare to be held in stock! Carolina Conveying offers a wide assortment of standard and custom rotary airlock valves. With different housings and numerous variations of rotor styles, vanes, tips, pockets, coatings and finishings, the applications that can successfully be installed are unlimited.

Carolina Conveying offers a wide assortment of standard and custom rotary airlock valves. With different housings and numerous variations of rotor styles, vanes, tips, pockets, coatings and finishings, the applications that can successfully be installed are unlimited.