Wash

Water Recycling

Wash

Water Recycling

Clayton Equipment Company offers a full line of water recycle and wastewater treatment equipment for wash water recycle, heavy metals removal, and oily wastes. Treatment steps include solids removal, organic removal, and oil removal.

Typical applications include vehicle washwater, golf course maintenance, equipment cleaning, industrial wastewater, marine bilge water and more.

It

all Starts in the Sump

It

all Starts in the Sump

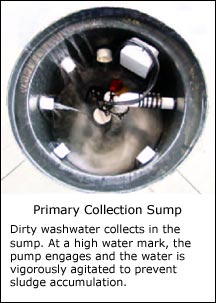

Specialized pumps, agitators and other features move the dirty water to the rest of the system where it is screened, filtered, clarified and stored. When needed for washing, the water then travels through final treatment of sand filtration, activated carbon adsorption and oxidation before being sent through the high pressure washing hoses.

Unlike biological systems, these activated carbon-based systems handle changes such as chemical and fuel leaks, temperature and pH variations, and temporary system shutdowns. Soaps, detergents and soil conditioners in the washwater also don't cause a foaming problem as they might in biological systems.

Employment of activated carbon adsorption, chemical precipitation and oxidation is listed by the USEPA in their published list of recommended treatment technologies.

Activated carbon systems can provide 20-30 GPM on a continuous basis and achieve zero discharge of pollutants.

Golf

Courses

Golf

Courses

Golf Course maintenance facilities generate wastewaters from turf vehicle washing, chemical mix & load, chemical storage, cold storage, maintenance shop and fueling operations. We offer an Integrated Chemical Management™ system, including a wash water recycling stage, that addresses all these issues.

Shown above is the compact Low Profile Wash water Recycle model with a capacity up to 30 gpm. All the models utilize state of the art EPA recommended technology for treatment of organic hydrocarbons including activated carbon adsorption and oxidation.

The Integrated Chemical Management™ system concept involves the arrangement

of the pads for the various functions so as to provide a containment envelope for all wash, chemical handling and fueling processes.

The Integrated Chemical Management™ system concept involves the arrangement

of the pads for the various functions so as to provide a containment envelope for all wash, chemical handling and fueling processes.

Any fuels, chemicals, sprayer solutions or wash waters released within the containment area are captured, segregated and either recycled or treated to prevent their release to the environment.

Click here to see a White Paper on the Golf Course maintenance Facility Integrated Chemical Management™ concept written by Austin R. Shepherd, P.E., VP - Technical Director of Carbtrol Corporation. Pages 1 & 2 describe the concept, page 3 summarizes the benefits and page 4 is a diagram of a typical layout.

Advanced

Wash Water System

Advanced

Wash Water System

The advanced Wash Water System is designed for larger golf course and fleet vehicle wash applications. Capable of up to 60 gpm it features free-standing tank capacities for the cone-bottom clarifier of 2,200 gal and for the treated water of 1,000 gal.

Wash Water Recycling Components

Wash Water Recycling Components

All systems feature a solids separation screen with a grass cart for easy management of dirt, rocks, and grass. The photo shows leaves and debris falling into the cart. The screened water moves through the PVC piping down into the wash water system.

For heavy metals removal and oily wastes, treatment steps include solids removal, organic removal, and oil removal. Equipment used includes ion exchange systems, activated carbon for removal of VOC's and chlorinated hydrocarbons, oil water separators, and solids filters.

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358