Index to News Articles

| Customer A Customer B |

A blending plant customer installs a new Central Vacuum System by American Vacuum

A blending plant customer installs a new Central Vacuum System by American Vacuum

Dust accumulation on plant floors and equipment can be an ongoing problem.

For assistance with their housekeeping needs and employee safety, this blending plant customer is now using an American Vacuum Central System with convenient hose connections throughout a plant. Vacuum operators can reach floors, mezzanines, walls and equipment using an appropriate wand and tool for each application.

Videos: Inspection, startup and vacuuming using a new American Vacuum Inc. Central Vacuum System

Videos: Inspection, startup and vacuuming using a new American Vacuum Inc. Central Vacuum System

Click on image to see a video play (.mov format) in Quicktime. Use browser back arrow to return to this page. Patience may be required depending on your download speed.

Vacuuming a plant mezzanine levels

Vacuuming a plant mezzanine levels

Vacuum system components while active

Vacuum system components while active

Photos: Inspection, startup and training of a new American Vacuum Inc. Central Vacuum System

Above: Startup precheck.

Above: The complete package / The PD blower-motor system / The receiver with door open revealing the dust bags.

Above: Closeups of the power package.

Above: Closeups of the power package and the drum top assembly.

Above: Closeup of receiver pulse system / The main inlet duct Y / A vacuum drop duct with tool flange

Above: Two additional vacuum drop ducts with tool flanges / Closeup of a vacuum drop duct with tool flange

Above: Closeup of the control panel / Customer training on the control panel

Above: Customer training on vacuum tool sets / Customer training on insertion of the vacuum hose

Above: Customer training on vacuum floor tool / Customer training on vacuuming floor surfaces

Above: Customer training on vacuum hand tool / Customer training on vacuuming surfaces on equipment and walls

Back to Index

A Texas manufacturing plant customer installs a new dual Central Vacuum System by American Vacuum

A Texas manufacturing plant customer installs a new dual Central Vacuum System by American Vacuum

Accumulating explosive dust on plant floors and equipment became a dangerous threat.

For assistance with their housekeeping needs and employee safety, this customer is now using dual American Vacuum Central Systems providing convenient hose connections throughout a multiple–building plant. Vacuum operators can reach floors, mezzanines, walls and equipment using the appropriate tool for each area. Two liquid separators are included for those spots that have water and fluids mixed with the dust.

Photos: Inspection, startup and training of new American Vacuum Inc. Dual Central Vacuum Systems

Above: System A on left, System B on right, both with 20 Hp motors and mezanine structures for maintenance .

Above: Making final start-up settings on System B; the taller structure and ladder just to the left is a large dust collector out of the photo.

Above: Jack Person, Amer Vac and Bob Foster, Air Quality Sys observing operating system including electronics and Explosion Relief Panel.

Above: Spring loaded inlet cap held open; 25' hose and tool set; motor and pump for System A.

Above: Inlet drop with bolted compression fitting next to a remote start stop; switch box and rotary valve on the receiver framework.

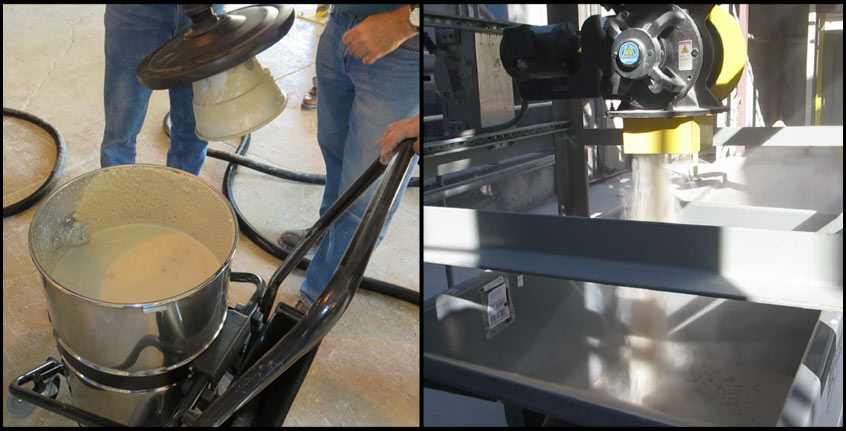

Above: Liquid and material spill, impossible for most vacuum systems, is being esaily vacuumed here. See next photo for why.

Above: Portable vacuum liquid separator accepts the mixture, sends dried material to the receiver and stores remaining liquid, easily dumped later with hinged container. Right photo: Dried material sent to receiver is shown discharging into customer's bin..

Back to Index

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358