Mechanical

The FlexMAX® flexible screw conveyor manufactured by Erie Technical Systems Inc. reliably feeds a variety of bulk materials and comes with an inlet hopper, screw casing, helical screw, discharge head and a motor with gear reducer. The FlexMAX® is commonly used with UltiMAX™ bulk bag unloaders, bag break stations or large storage hoppers.

The FlexMAX® flexible screw conveyor manufactured by Erie Technical Systems Inc. reliably feeds a variety of bulk materials and comes with an inlet hopper, screw casing, helical screw, discharge head and a motor with gear reducer. The FlexMAX® is commonly used with UltiMAX™ bulk bag unloaders, bag break stations or large storage hoppers.

Features

• Low-cost screw conveyors for quick delivery

• true 60° feed hopper sides and FASTFLO rounded corners eliminae product hold up

• A flexible tube for routing around fixed objects

• Dust-tight, completely enclosed

• Low maintenance with only one moving part

• Simple disassembly for easy cleaning

• 3", 4”, 5" and 6” nominal sizes for a wide range of flow rates

• Feed rates up to 450 cubic ft/hour in conveyor lengths up to 40 ft

• Product contact surfaces in 304SS and UHMWPE

• Add-on options for a custom machine

Erie Technical Systems Spiral Elevator

The SpiralMAX® vibratory spiral elevator is a unique solids conveying conveyor used to move material vertically either up or down a spiral flight. It offers significant advantages over traditional belt conveyors or drag conveyors including a much smaller footprint and no moving parts in the product stream.

The SpiralMAX® vibratory spiral elevator is a unique solids conveying conveyor used to move material vertically either up or down a spiral flight. It offers significant advantages over traditional belt conveyors or drag conveyors including a much smaller footprint and no moving parts in the product stream.

Features

• Discharge heights as high as 25 ft

• Material transfer rates as high as 500 cubic ft/hr

• Stainless steel or carbon steel construction

• Quiet Trouble-free long term operation

• No moving parts in product contact

• Gentle transfer to reduce product breakage

• Optional Custom hoppers and chutes to match existing equipment

• Optional Dual magnetic starter for the rotary electric vibrators

• Optional Dimple Plate flights and Cooling jackets

• Optional Dewatering cutouts and water collection

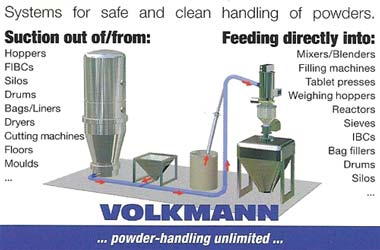

Volkmann high-quality, high-performance pneumatic vacuum conveyors, bulk bag unloaders, rip and tip stations, hoists, delumpers, dust collection systems, and weighing and dosing systems offer a complete, fully contained powder handling system for the safe material transfer of fine chemicals, granules, pellets, tablets and small components.

Volkmann high-quality, high-performance pneumatic vacuum conveyors, bulk bag unloaders, rip and tip stations, hoists, delumpers, dust collection systems, and weighing and dosing systems offer a complete, fully contained powder handling system for the safe material transfer of fine chemicals, granules, pellets, tablets and small components.  Volkmann systems are particularly well-suited to dust-tight, segregation-free and damage-free powder handling under vacuum. With features such as “No-Tools” disassembly and easy cleaning, as well as designs conforming to cGMP standards, air-driven Multijector® vacuum generation and ATEX certification for explosion-proof applications – it’s no wonder Volkmann is leading the industry with powder and granule pneumatic conveying solutions.

Volkmann systems are particularly well-suited to dust-tight, segregation-free and damage-free powder handling under vacuum. With features such as “No-Tools” disassembly and easy cleaning, as well as designs conforming to cGMP standards, air-driven Multijector® vacuum generation and ATEX certification for explosion-proof applications – it’s no wonder Volkmann is leading the industry with powder and granule pneumatic conveying solutions.