Dings magnetic group and Advanced Detection Systems

Dings offers a complete line of magnetic separators for recovering materials, ensuring product purity and protecting your equipment. Advanced Detection Systems manufactures a wide range of industrial metal detectors designed to protect valuable processing equipment and avoid costly downtime.

Dings OH Electro Self Clean magnet with CR Belt

Dings OH Electro Self Clean magnet with CR Belt

Overhead or Overband magnetic separators suspend above belt or vibratory conveyors, magnetically lifting ferrous metals out of bulk material. They are used for steel recovery; or protecting processing equipment, removing damaging tramp metal that can cause costly repairs and downtime.

A belt travels around the body of the magnet to discharge ferrous metals; Separation is high-volume, continuous and automatic. Recovered metal objects are removed automatically from the magnetic zone.

Common applications include Mining, Aggregate, C&D Recycling, Municipal Recycling, and Foundry. The severe duty Overhead electromagnet option is ideal for Concrete Recycling and can be used in most demanding applications.

Other Overhead Magnets

Other Overhead Magnets

The Permanent Stationary maintenance-free design has no moving parts and requires no power supply. Just suspend it over the conveyor or over the head pulley and it's ready to pick up stray metal fragments before they can cause damage to downstream equipment.

The Electro Stationary Magnet is a good choice for separation of tramp metal. Just suspend it over the conveyor or over the head pulley. When the magnet surface starts to fill up, swing the magnet away from the conveyor and cut the power to release the attracted metal.

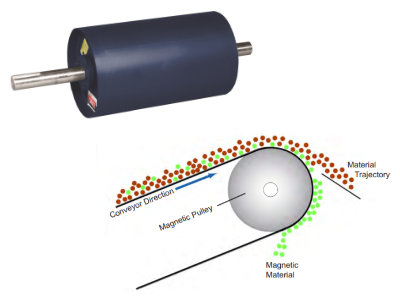

Magnetic Pulley

Magnetic Pulley

Magnetic Head Pulleys are permanent magnetic separators that operate as head pulleys on belt conveyors. These self-cleaning magnets remove tramp iron and purify material conveyed in bulk form. Separation is automatic and continuous.

Magnetism is permanent, never weakens, provides long life with no corrosion. Installation is easy, just install belt around pulley. Diameters range from 6" to 42", widths to 84" +.

A Dings magnetic head pulley costs nothing to operate. Its permanent magnetic strength is available around the clock with no need for an external power source, extra mounting hardware or special maintenance.

ADS Protector

ADS Protector

The ADS Defender III offers adjustable RF protection helping to compensate for environmental noise and power fluctuations, a patented coil auto-balance technology eliminating the need to re-balance the coil, digital control and processing with two channel detection, and data retention when power is disrupted or disconnected.

The SurroundScan Protector-HD detects ferrous and nonferrous tramp metal, prevents damage to rock crushing equipment. The Protector-HD is designed for installation on flat-belt and trough-belt conveyors. Full PLC integration allows for line shutdown, or local control of the conveyor can be given to the detector.

Rugged, heavy-duty steel construction is designed to take a beating and keep on running. An armored chassis protects the coils and the internal wiring and electronics. Chassis fits into standard sized rails with minimal modifications and the removable side plate means you don't have to cut a belt, or unsplice it, to install. Patented digital technology ensures that the detector will work in any environment and can be set to tune out the small pieces that won't cause harm and only detect the larger pieces that could damage downstream equipment. The Protector auto-balances and auto-learns product, eliminating rebalancing procedures and the guesswork associated with analog "radio knob" controls. A variety of metal marking systems are available to allow you to readily locate the metal, remove it, and get back to business. Programmable contacts for full PLC integration and reject-device control for automated control of waste gates or belt plow systems.

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358