Container Washing Systems by

Container Washing Systems by

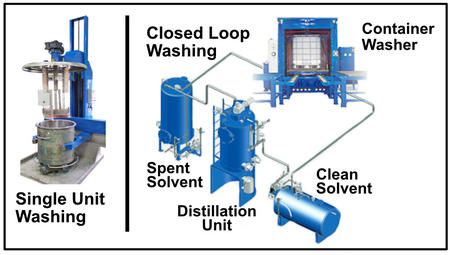

PRI™ Container Washing systems are available in single container wash units to closed-loop system integrations into your water treatment system, production assembly line, paint filling line, or solvent recovery system. In this process, spent solvent is collected and fed into a distillation unit, where the contaminants can be separated from the reusable solvent. Contaminants are discarded and reusable solvent is automatically fed back through the cleaning process.

PRI's line of wash systems are designed for a variety of applications, and can be used to clean grease, oil, automotive lubricant, paint, coating, ink and more. Systems can be designed to use aqueous, caustic or solvent cleaning chemistries.

Mixing Vessel Washers

Mixing Vessel Washers

Gemini by PRI™ GemiClean (Model VW) is designed for cleaning mixing vessels by a rotating brush and a spray nozzle assembly that self-adapts to the height and diameter of each vessel. The vessel is clamped in position by downward force by the lock-up cover. A tilting platform enables complete emptying of the vessels into a sedimentation or distillation system, to separate sediment from the cleaning agent and recycle. Features include brush and spray cleaning; interior cleaning; wash, rinse, dry cycles and fume venting systems. The GemiClean has a compact footprint, pneumatic controls and is explosion-proof.

The RotaJet by PRI™ (Model PW) is designed for cleaning mixing vessels placed on the lifting lid. Once locked into position, the vessel is loaded into the wash chamber using a hydraulic jack system. The cleaning process is fully automated, and the vessels are washed, rinsed and dried, ready for production. Fumes are vented prior to opening the system, to limit employee exposure. The RotaJet features high pressure spray cleaning; interior and exterior cleaning; and wash, rinse, dry cycles. It has a fume venting system, pneumatic controls and is explosion-proof.

Drum and Pail Washers

Drum and Pail Washers

RotaJet by PRI™ (Model TL-DR-55) drum washing machines are designed for low flash point flammable solvent cleaning. Dirty, open-top 55 gallon drums are loaded into the machine, the door is closed and cycle started. The cleaning process is fully automated, and the drums are washed and ready for production. Cycle times are approximately 5 minutes. Features include simple design and operation; high pressure spray cleaning; interior cleaning only; and wash, rinse, dry cycles. They offer a compact footprint and explosion-proof pneumatic controls.

The RotaJet by PRI™ (Model D-40) batch pail washing system is designed for low flash point flammable solvent cleaning. Dirty containers are loaded into the machine, the door is closed, and cycle started. The cleaning process is fully automated, and the containers are washed, rinsed and dried, ready for production. This RotaJet features high pressure spray cleaning; interior and exterior cleaning; wash, rinse, dry cycles; and a fume venting system. It has a compact footprint and explosion-proof pneumatic controls.

IBC, Tote, Drum & Pail Washers

IBC, Tote, Drum & Pail Washers

RotaJet by PRI™ (Model D-60) drum, IBC, tote and pail washer systems are flexible to wash multiple container types.

The systems can be used for decontamination of IBC’s prior to disposal, or cleaning for in-house production. The modular system design allows customers to increase capacity by adding additional units. Once a wash cycle is complete, the interior of the wash chamber is vented prior to door opening, limiting employee contact with fumes.

© 2023 Clayton Equipment Company LLC • North Texas Office (214) 696-6960 • Gulf Coast Office (254) 644-5358